PEBCO®’s line of Mass Flow Feeders and Rolling Blade Belt Feeders are engineered to provide exceptional accuracy and uniformly load the belt on centerline every time, regardless of flow rate. Simple, reliable designs require little maintenance and provide more up time over the life of the system than any other feeder technology. By actively compensating for head load, moisture, product size, segregation, and demand, our feeder systems improve your ability to respond quickly and accurately to the demands of the process.

From single-point discharges to multi-point blending applications, under mass flow or funnel flow silos or hoppers, and even stockpiles; PEBCO®’s expertly engineered family of feeders will give you the ability to deliver the right amount of product every time.

Mass Flow Feeders offer incredible accuracy for critical feed rates or blending applications with repeatable accuracies of <1% and maximum to minimum flow ratios as high as 10:1. Rolling Blade Belt Feeders get the material moving in the same direction as the conveyor prior to contact with the belt to increase the life of the belting. Call one of our experienced Sales Engineers today to talk about which one is best for your project.

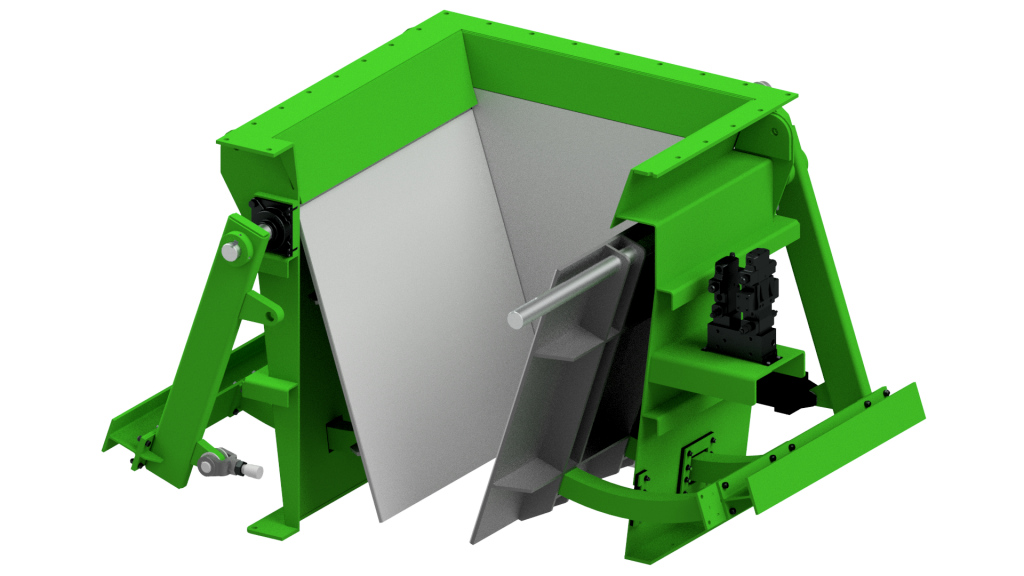

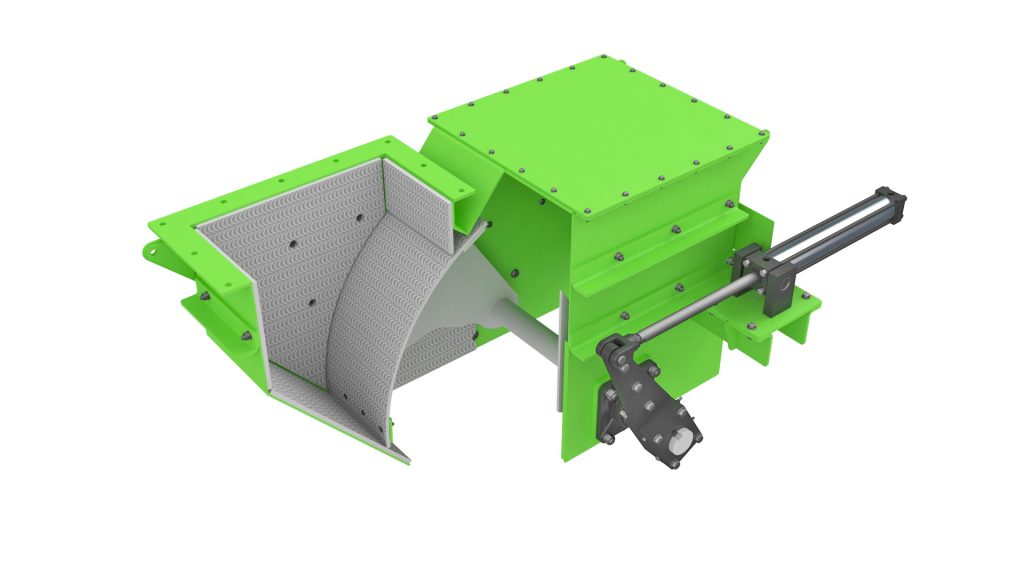

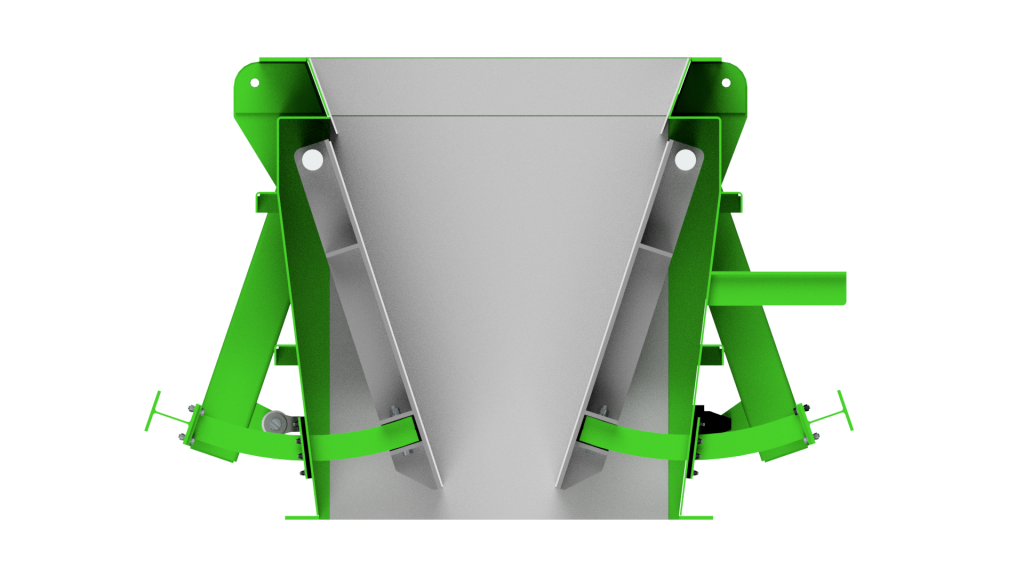

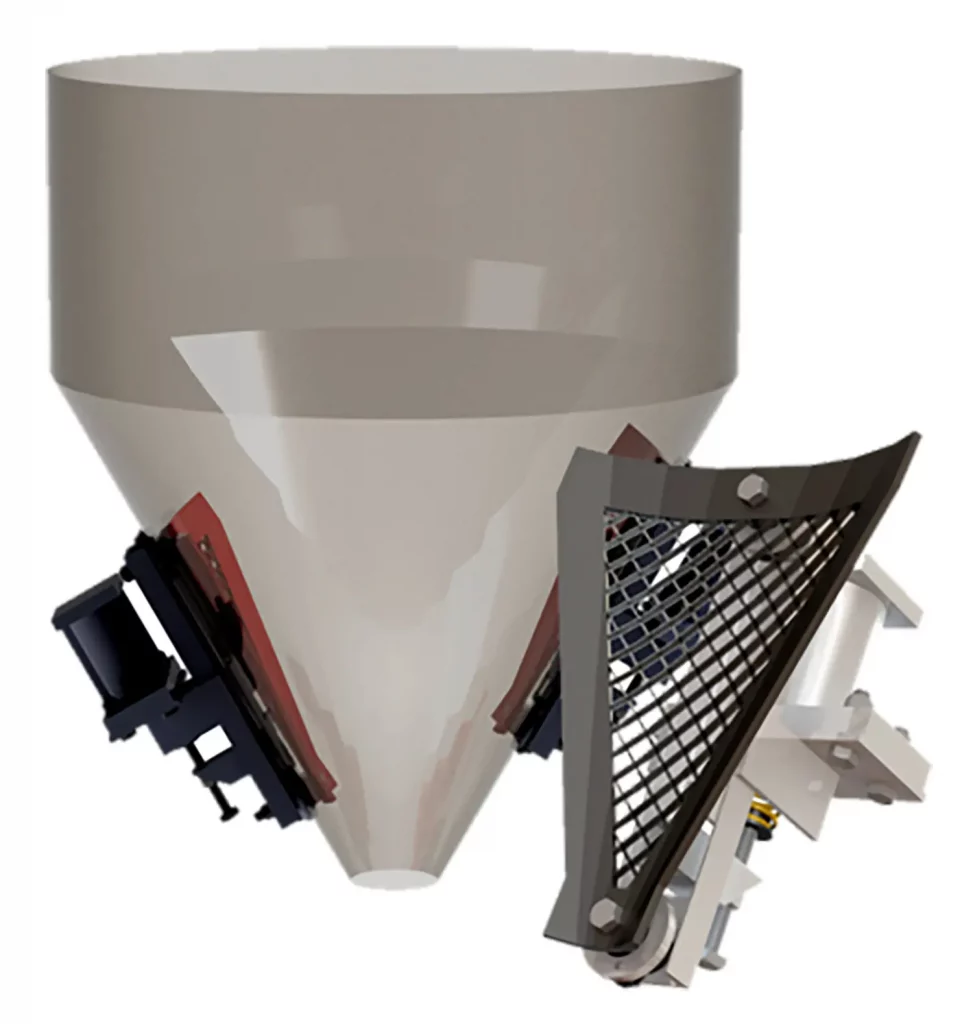

Double Blade Mass Flow Feeder (DBMFLO)

The PEBCO® Double Blade Mass Flow Feeder accurately meters material onto the centerline of a conveyor. Double Blade Mass Flow Feeders are used in single point flow control and multi-point blending systems.

- Typically used to precisely meter material onto a conveyor belt in feeding or blending applications

- Flow rates from 50-8000 TPH with turndown ratios up to 10:1

- Promotes mass flow of material and is ideally suited for use at the discharge of a mass flow silo/hopper

- Also provides accurate flow regulation under funnel flow silos/hoppers and open stockpiles.

- Synchronized blade movement insures centered feed onto the belt at all flow rates

- Hydraulic cylinders with position feedback accurately position and hold blades to obtain the desired flow rate

- Feeder design prevents flush-through of material under rail dumps and in case of rat-hole or bridging collapse

- No vibrating and few moving parts:

- Provides long operational life

- Minimum maintenance requirements

- Totally enclosed design eliminates dust emissions and can be easily integrated into conveyor enclosures

- Low energy consumption and noise levels as compared to other feeder designs

- Multiple feeders can be combined with belt scales to precisely blend product

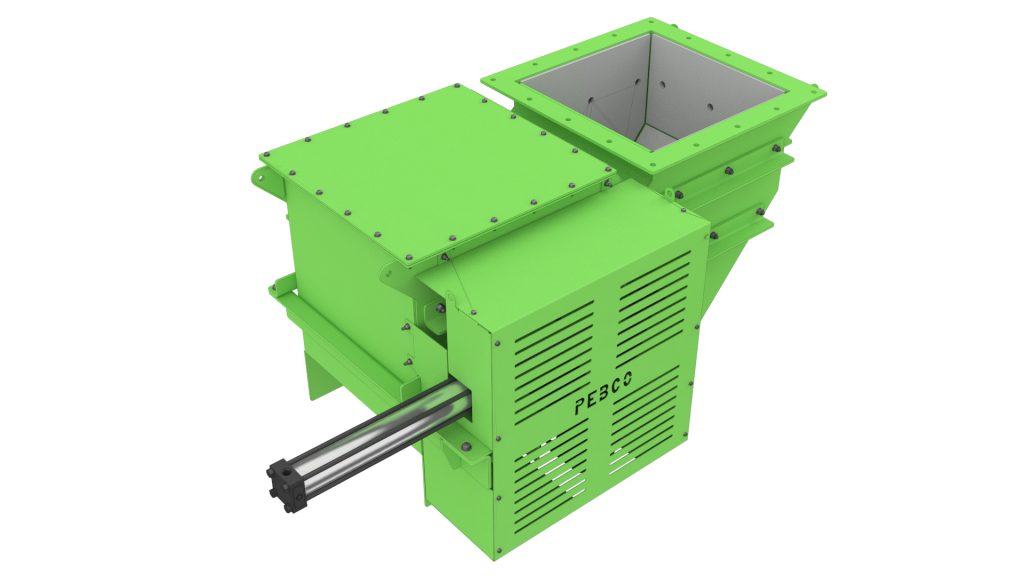

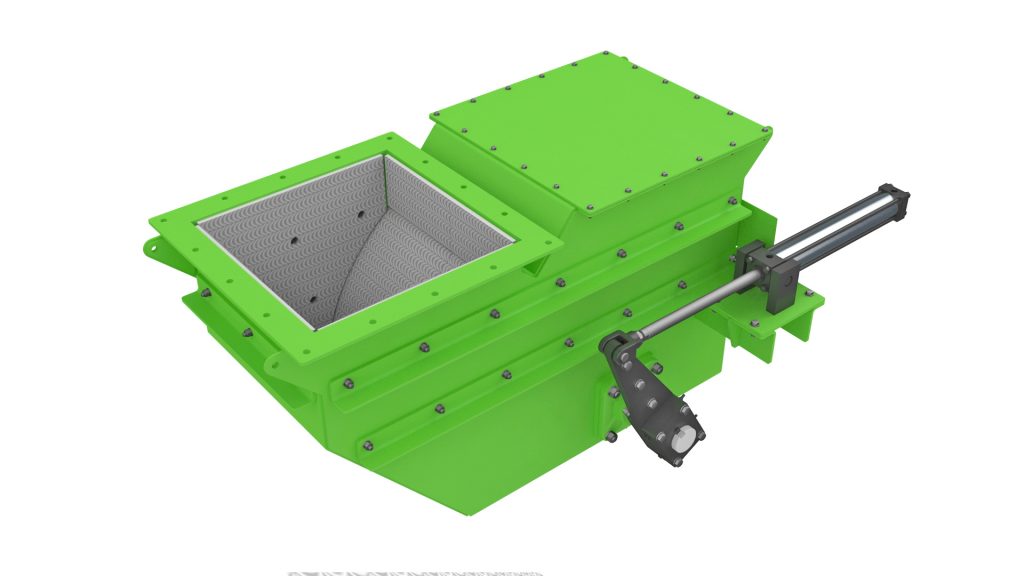

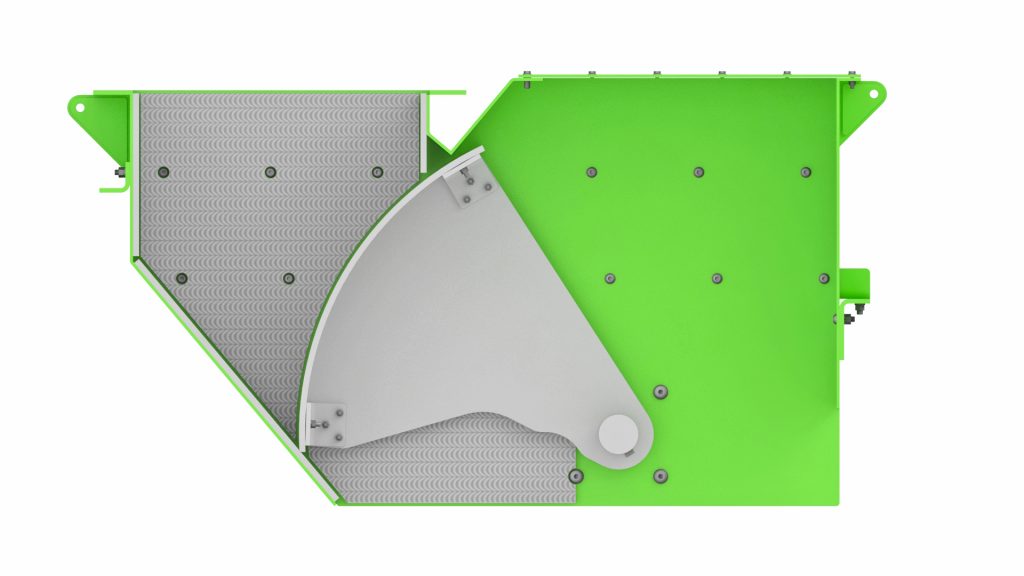

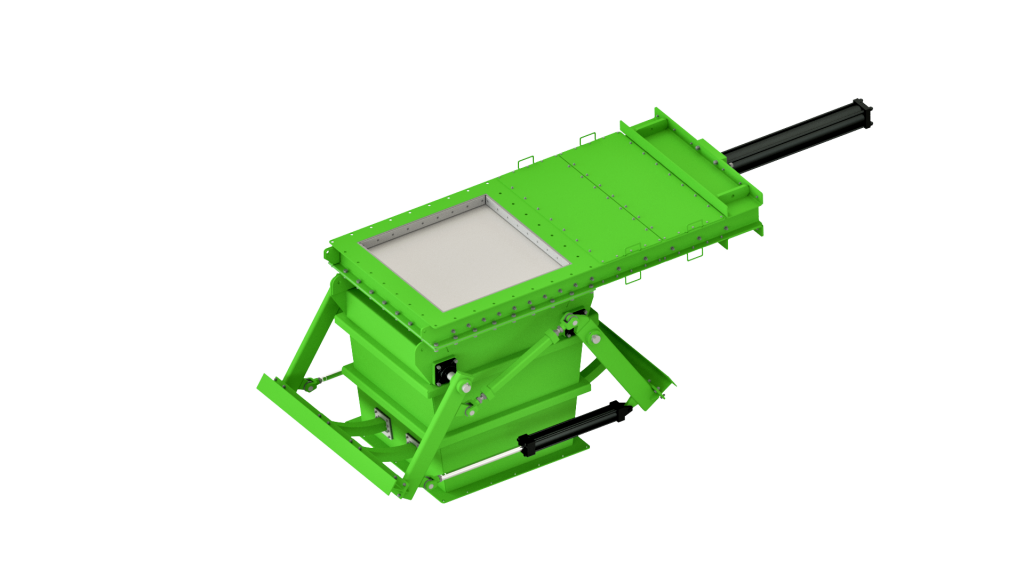

Rolling Blade Belt Feeder (RBBF)

PEBCO® Rolling Blade Belt Feeders feature a unique design that provides precise material flow regulation, positive material shut-off, as well as eliminating dust emissions.

- Introduces flow in the direction of belt travel

- Chute is incorporated into the feeder

- Totally enclosed design eliminates dust emissions and can be easily integrated into conveyor enclosures

- Flow termination ability

- Curved blade promotes precise flow regulation

- Cam action provides positive seal when closed

- Multiple actuation options