Bulk Material Handling & Process Equipment

PRODUCTS

A Wide Range of Solutions

We provide solutions to industry challenges by connecting customers, manufacturers and industry professionals, to advance capabilities and technology.

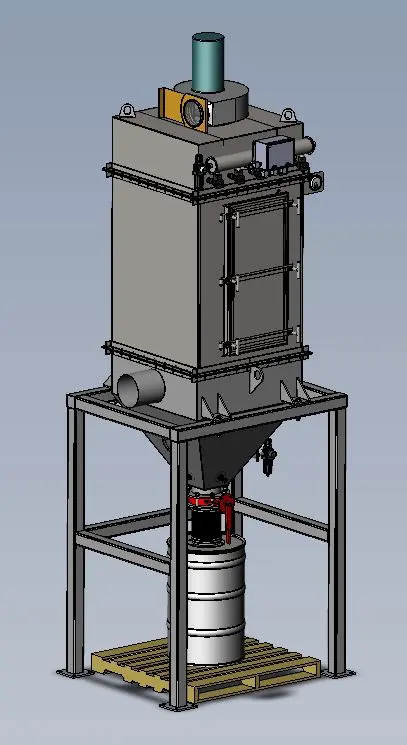

- Air Pollution Control

- Bag Unloading Systems (Manual and Automated)

- Bulk Bag Loading and Unloading

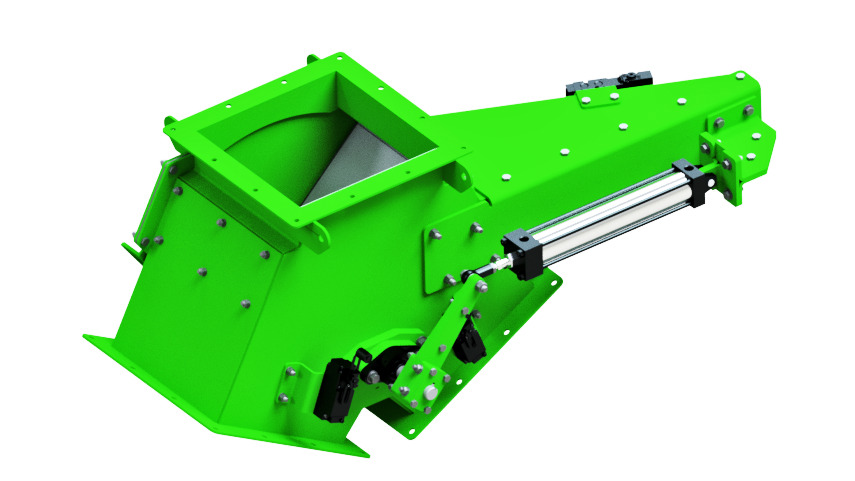

- Diverter Valves (Gravity Flow)

- Flow Control Valves (Gravity Flow)

- Industrial Ovens

- Industrial Vacuum Systems

- Loading Spouts

- Magnets

- Metal Detection

- Mechanical Conveying Equipment

- Mixing and Blending

- Packaging Equipment

- Palletizing Equipment

- Particle Classification/Separation

- Pneumatic Conveying Equipment

- Pneumatic Conveying Components and Accessories

- Rotary Valve/Air Locks/Double Dump Valves

- Silo and Bins

- Size Reduction

- Transloading Equipment

- Weighing and Feeding

- Wear and Abrasion Resistant Materials

MANUFACTURERS

Trusted Brands

Covering Iowa, Kansas, Missouri and Nebraska, we have partnered with industry leading suppliers of bulk material handling, process equipment, parts, service and speciality materials to support industrial manufacturing plants across our region.

Prairie States Industrial Supply is a manufacturer’s representative firm with over 25 years of industrial experience.

150 TPH Cement Rail Car Unloading System

Prairie States Industrial Supply received a request to supply the necessary equipment to unload cement from railcars along a rail siding. The customer wanted to

LATEST CASE STUDY

Drop us a line!

"*" indicates required fields