CHROMEWELD™ proprietary chemistries and unique manufacturing processes creates the widest range of premium quality overlay plate in the industry.

Each of our seven (7) grades of CHROMEWELD™ is developed to combat a specific wear challenge. From extreme abrasion, high impact or ultra-demanding unique conditions, there is a grade of CHROMEWELD™ that stands up to the most demanding wear conditions imaginable.

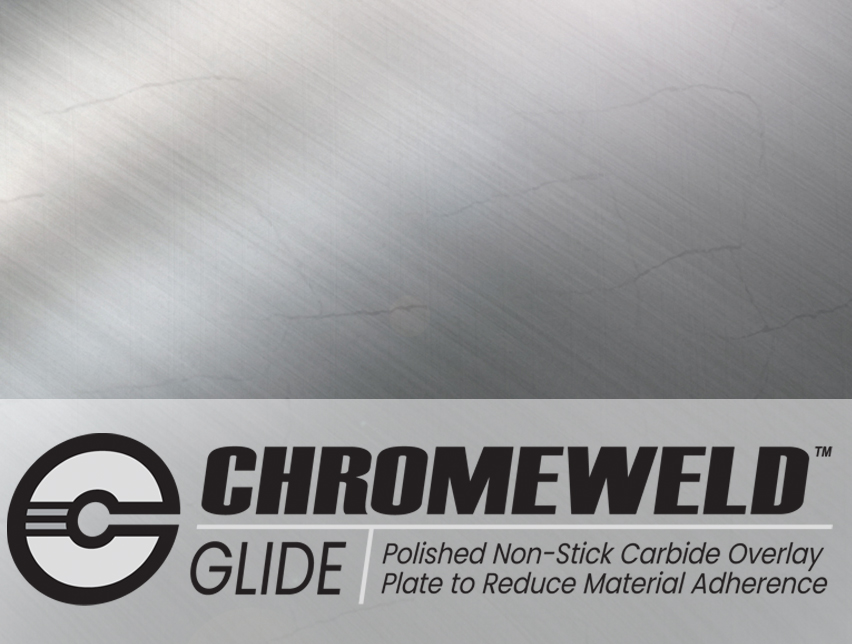

Manufactured with an A36 base material our Chromium Carbide Overlay offers excellent abrasion resistance against sliding abrasion with 7-10 times the life of a commodity AR plate. Available in 1/8″ on 1/8″ to 1/2″ on 1″ with a standard plate size of 90″ x 120″.