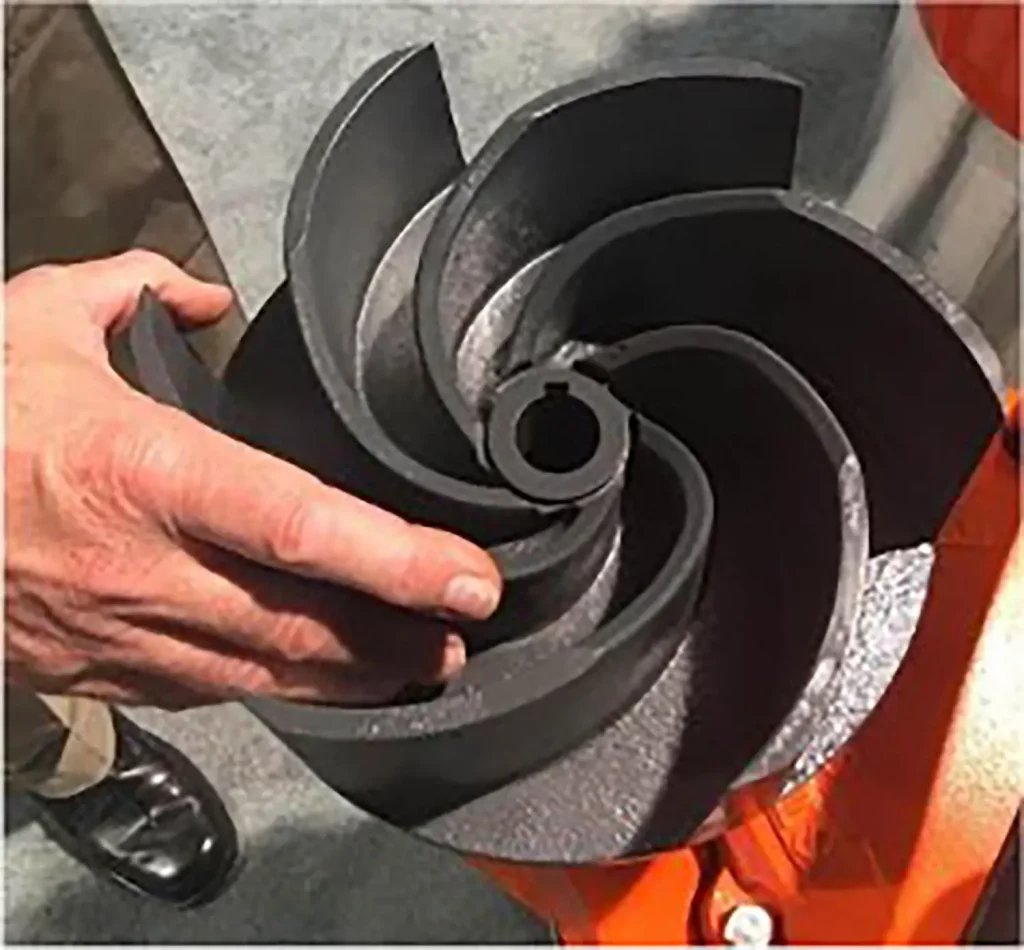

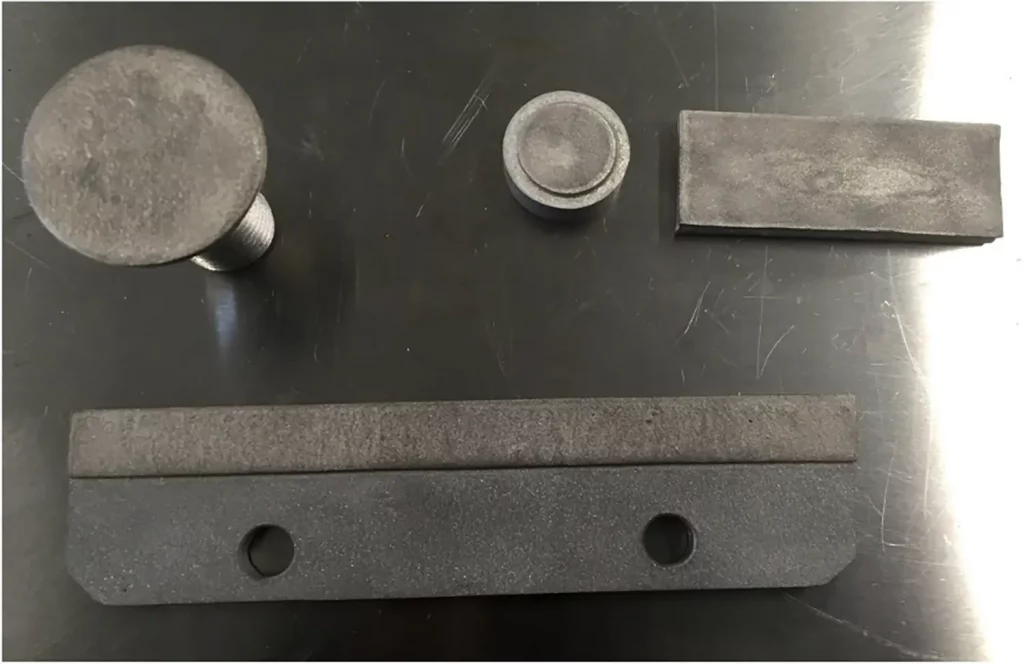

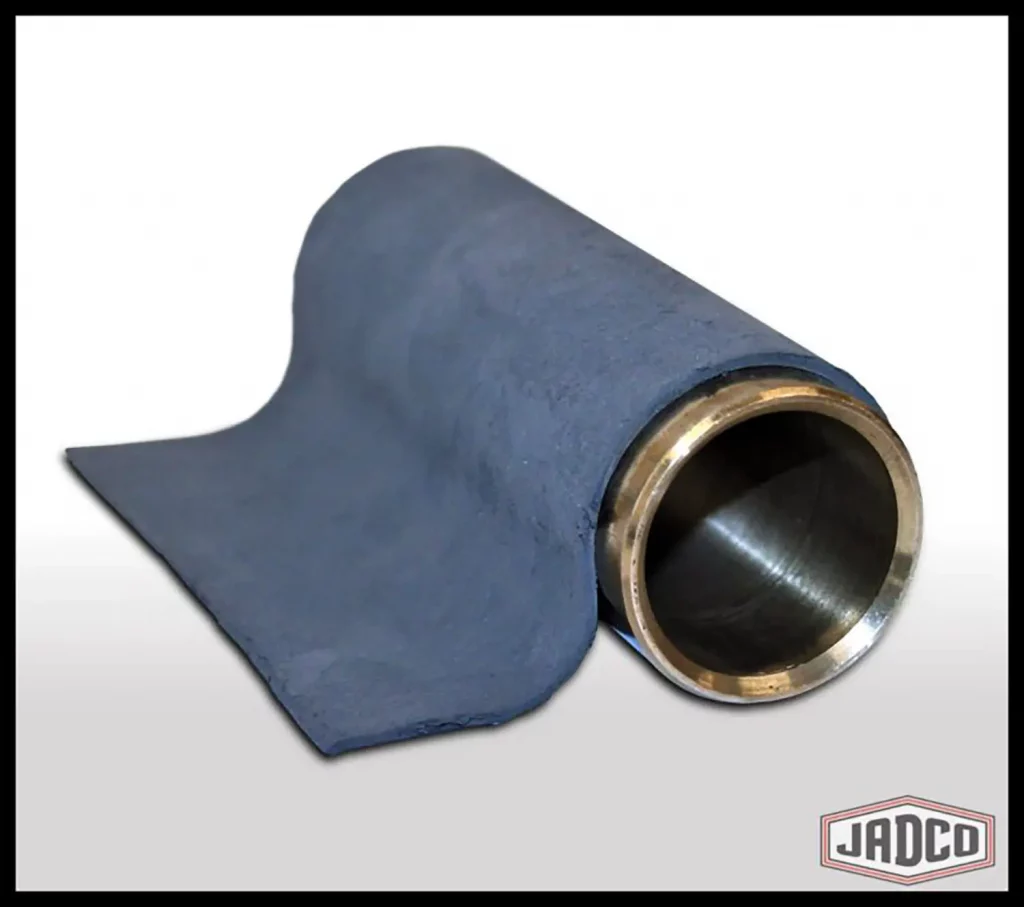

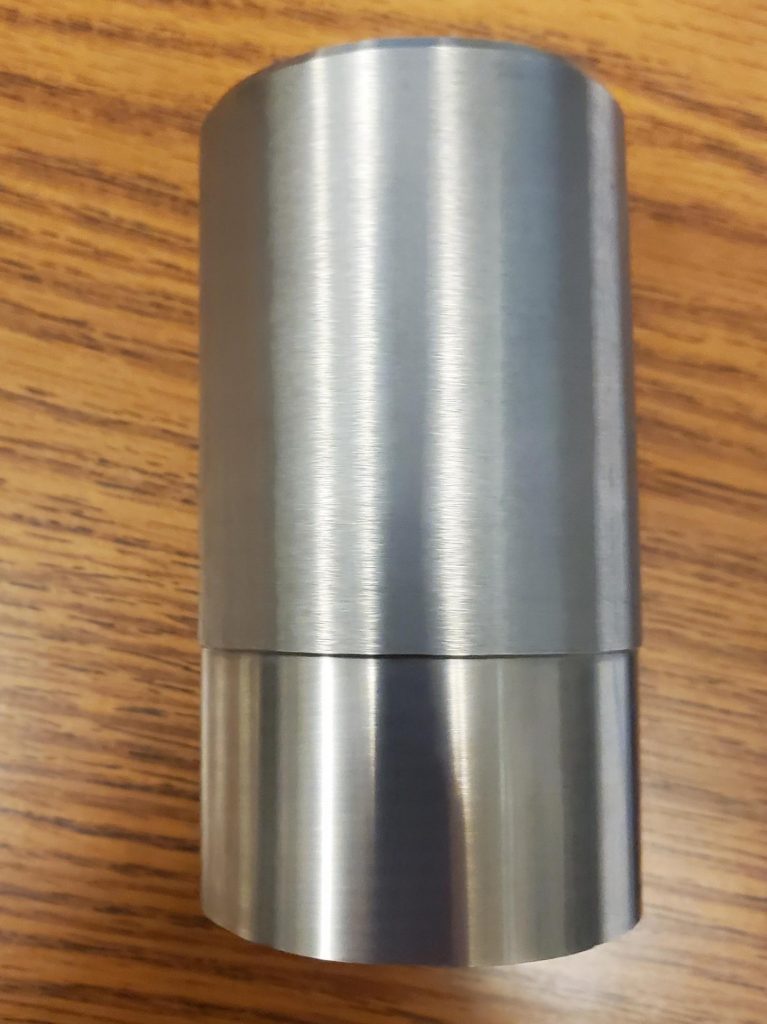

FLEXWEAR™ is a cloth-like cladding that encases and covers hard-to-protect complex-shaped parts. It is comprised of fine tungsten carbide particles suspended in a nickel matrix that is adhered to high wear components of nearly any geometry. Our proprietary “infiltration brazing” process creates a metallurgical bond between the tungsten carbide and the substrate to deliver the ultimate level of wear resistance. The tungsten carbide-filled cladding offers the utmost resistance to abrasion, corrosion and erosion due to the small particles used in the cloth.

Mechanical Information

The typical hardness of FLEXWEAR™ is up to 72 HRC and the strongest bond is >70,000 psi. The tungsten carbide is uniformly bonded and distributed throughout the nickel alloy matrix with a resulting coating which has a smooth surface with little to no porosity. The braze process is done at 2000ºF. Coating thicknesses range between 0.030” to 0.120”. FLEXWEAR is resistant to corrosion and erosion at elevated temperatures.

Features

• Light weight Superior abrasion resistance than chromium carbide overlay

• Superior corrosion and erosion resistance than stainless steel Higher temperature resistance than 304 stainless steel

Benefits

• Longer Life

• Less Downtime

• Increased Production

• Reduced Maintenance Costs

• Increased Profitability